How to Choose the Best Electric Cement Mixer for Your Needs?

Choosing the best Electric Cement Mixer is vital for construction efficiency. The global market for electric mixer equipment has been projected to grow significantly, driven by the rising demand for time-saving construction solutions. Reports indicate that the electric mixer market could see a growth rate of around 7.3% annually over the next few years.

When selecting an Electric Cement Mixer, consider the capacity and power options available. A mixer that fits your specific task will enhance your productivity. Many users find themselves overwhelmed by choices and may overlook essential features. This can lead to dissatisfaction, hindering project timelines.

It's crucial to align your needs with the right equipment. A mixer’s design, mixing capacity, and durability play a significant role in its effectiveness. However, many tend to gravitate toward the most expensive models, assuming they are the best. A balance between cost and utility is essential. Doing thorough research and comparing models is key to making an informed choice.

Understanding Your Mixing Needs and Project Requirements

Understanding your mixing needs is crucial when selecting an electric cement mixer. Different projects require different mixing capabilities. For small DIY jobs, a compact mixer with a capacity of 2 to 3 cubic feet might suffice. This size is manageable and easy to operate. However, for larger projects, such as residential construction, a mixer with a capacity of 6 cubic feet or more is often necessary.

Research shows that a mixer’s power rating significantly impacts its performance. Most electric mixers range from 1 to 2 horsepower. A study indicates that a 1.5-horsepower mixer can effectively handle mixes with higher viscosity, making it suitable for heavy-duty tasks. Choosing a mixer with insufficient power may lead to motor burnout or inconsistent mixtures. Therefore, it’s essential to reflect on your project scale and the material you plan to mix.

When assessing your requirements, consider factors such as portability and ease of cleaning. Some mixers are lightweight and easy to maneuver. Others, while providing more power, can be cumbersome. Also, consider the mixer’s design, as a poorly designed unit may leave trapped material, leading to waste. These reflections can help you choose a mix that aligns with your project's demands and personal workflow.

Key Features to Look for in an Electric Cement Mixer

When selecting an electric cement mixer, key features can greatly influence your project’s success. Motor power is critical. A mixer with at least 1.5 to 2.0 horsepower is ideal for heavy-duty jobs. This range increases efficiency and reduces mixing time. According to industry reports, a robust motor can handle thicker mixtures without strain, providing better consistency.

The drum capacity also matters. Mixers with 2 to 3 cubic feet are suitable for most home projects. However, larger capacities are available for extensive jobs. A larger drum means you can mix more material at once, saving time. Pay attention to the build quality as well. A durable frame can prevent wear and tear over time. Aluminum or stainless steel drums are typically easy to clean and maintain.

Portability should not be overlooked. Choose a model with wheels for easy transport. Weight distribution is another factor; a well-balanced mixer can reduce fatigue and risk during operation. Some users find the learning curve steep, especially with complex controls. This can lead to inefficient mixing or user errors. Adjusting to the mixer’s handling needs practice, and oversight can compromise the quality of your mixture.

How to Choose the Best Electric Cement Mixer for Your Needs? - Key Features to Look for in an Electric Cement Mixer

| Feature |

Description |

Importance |

| Drum Capacity |

Refers to the volume of cement that can be mixed at once |

Determines how much material you can mix, crucial for larger jobs |

| Power |

Measured in watts, it indicates the mixing power and efficiency |

Higher power means faster and more effective mixing |

| Weight |

The overall weight of the mixer |

A sturdy mixer is generally more stable during operation |

| Mixing Speed |

The rate at which the mixer can rotate the drum |

More speeds can provide better control over mixing |

| Ease of Use |

Includes features like portability and controls |

Easy-to-use mixers can save time and reduce effort |

| Durability |

Materials used to construct the mixer |

A durable mixer will last longer and require fewer repairs |

| Safety Features |

Includes functions like overload protection and emergency stops |

Enhances user safety during operation |

Comparing Different Types and Sizes of Electric Cement Mixers

Choosing the right electric cement mixer requires understanding the types and sizes available. Electric cement mixers come in various sizes, typically ranging from 1 to 6 cubic feet. A smaller mixer may suffice for small projects like garden paths. However, larger construction jobs may necessitate a capacity of 4 cubic feet or more. According to a report by the Construction Industry Council, choosing the right size can significantly impact efficiency and material handling.

Different types of mixers exist. There are portable mixers, which are ideal for DIY projects. They are lightweight and easy to move. On the other hand, stationary mixers can handle larger batches. Data from the National Association of Home Builders suggests that more than 60% of home projects require at least one large batch of mixed material. The requirement for durability and performance weighs heavily on mixer selection.

Cost is another factor to consider. Budget constraints often lead to compromises. Many users find themselves reconsidering their choices after realizing that a less expensive model struggles under heavier usage. Feedback from contractors often highlights the need for a balance between cost and functionality. Investing in a suitable size and type of mixer is crucial for long-term satisfaction and productivity in construction projects.

Evaluating Power and Performance Specifications

When evaluating the power and performance specifications of electric cement mixers, consider the motor wattage first. A powerful motor ensures that the mixer can handle heavy materials without overloading. Many models on the market range from 600 to 1500 watts. Choose one that suits the scale of your projects. For small jobs, a lower wattage might suffice. However, an underpowered mixer can struggle, leading to frustrating delays.

Next, examine the mixing capacity. Most mixers list their drum capacity in liters. This factor determines how much material you can mix in one go. A larger drum may seem appealing, but remember that it can be cumbersome. You might need to adjust your mixing technique based on the machine's size. Sometimes, smaller batches are easier to manage and yield better consistency.

Also, don’t forget to check the speed settings. Some mixers offer variable speeds, which can be beneficial. Higher speeds blend quickly, while lower speeds are ideal for delicate jobs. It’s a balancing act, as too much power can create a mess. Experimenting with speed is essential to find what works best for your unique needs.

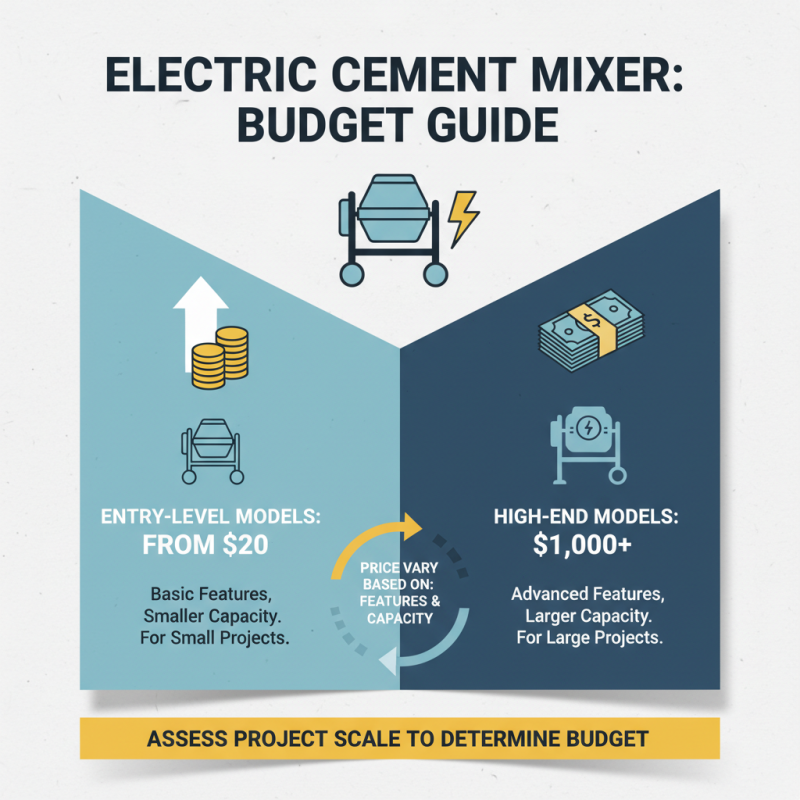

Budget Considerations and Recommended Brands to Explore

When selecting an electric cement mixer, budget is crucial. According to industry reports, entry-level models can start around $200. Higher-end mixers can exceed $1,000. Prices vary widely based on features and capacity. Assessing your project scale helps determine your budget.

Investing wisely is essential. Some high-priced models might seem appealing due to their features. Yet, they may not align with your needs. For smaller tasks, a less expensive option might suffice. Look for mixers with at least a 3.5 cu. ft. capacity for most DIY projects. This size balances cost and performance effectively.

Be cautious of online reviews. While many can provide insight, some may be biased. User feedback often highlights durability issues in lower-end models. Researching reputable sources can guide you to trusted options. These details ensure you make a sound purchase decision. Remember, a well-chosen mixer can save time and effort in the long run.

Home

About Us

Products

Concrete Mixing Plant

Concrete Mixing Plant

HZS Series Belt Concrete Mixing Plant

HZS Series Belt Concrete Mixing Plant

HZS Series Bucket-Lifting Type Container Concrete Mixing Plant

HZS Series Bucket-Lifting Type Container Concrete Mixing Plant

HZS60 Mobile Concrete Mixing Plant

HZS60 Mobile Concrete Mixing Plant

HZS Series Bucket-Lifting Type Concrete Mixing Plant

HZS Series Bucket-Lifting Type Concrete Mixing Plant

HZS Series Mobile Concrete Mixing Plant

HZS Series Mobile Concrete Mixing Plant

HZS Series Top-Mounted Concrete Mixing plant

HZS Series Top-Mounted Concrete Mixing plant

HZS Series Semi-Top Mounted Concrete Mixing Plant

HZS Series Semi-Top Mounted Concrete Mixing Plant

Stabilized Soil Mixing Plant

Stabilized Soil Mixing Plant

Asphalt Mixing Plant

Asphalt Mixing Plant

Sand & Gravel Crushing and Screening Plant

Sand & Gravel Crushing and Screening Plant

RTPF350DS Crawler Mobile Impact Crushing Plant

RTPF350DS Crawler Mobile Impact Crushing Plant

RT116JH Crawler Mobile Jaw Crushing Plant

RT116JH Crawler Mobile Jaw Crushing Plant

RT116JE Crawler Mobile Jaw Crushing Plant

RT116JE Crawler Mobile Jaw Crushing Plant

RT300CE Crawler Mobile Cone Crushing Plant

RT300CE Crawler Mobile Cone Crushing Plant

RT300CH Crawler Mobile Cone Crushing Plant

RT300CH Crawler Mobile Cone Crushing Plant

RT5015H Mobile Scalping Screen

RT5015H Mobile Scalping Screen

RT315VSIE Crawler Mobile Sand Maker

RT315VSIE Crawler Mobile Sand Maker

RT3YK6020 Crawler Mobile Screening Plant

RT3YK6020 Crawler Mobile Screening Plant

RT3YK6020M Modular Screening Plant

RT3YK6020M Modular Screening Plant

RTF260M Modular Counterattack Crushing and Screening Integrated Machine

RTF260M Modular Counterattack Crushing and Screening Integrated Machine

RTF350M Modular Impact Crushing Plant

RTF350M Modular Impact Crushing Plant

RTF450M Modular Impact Crushing Plant

RTF450M Modular Impact Crushing Plant

Construction Waste Resourceful Treatment Line

Construction Waste Resourceful Treatment Line

Performances

Video

News

Blog

Contact Us

WDB Series Foundation-Free Stability Soil Mixing Plant

WDB Series Foundation-Free Stability Soil Mixing Plant LCB Series Emulsified Asphalt Cold Regeneration Secondary Mixing Plant

LCB Series Emulsified Asphalt Cold Regeneration Secondary Mixing Plant LB Series Asphalt Mixing Plant

LB Series Asphalt Mixing Plant LBR Series Integrated Asphalt Mixing Plant

LBR Series Integrated Asphalt Mixing Plant LBRN Series Counterflow Integral Asphalt Mixing Plant

LBRN Series Counterflow Integral Asphalt Mixing Plant RZS Series Asphalt Mixing Plant

RZS Series Asphalt Mixing Plant RTZS120 Series RAP Crushing & Screening Plant

RTZS120 Series RAP Crushing & Screening Plant Construction Waste Resourceful Treatment Line

Construction Waste Resourceful Treatment Line