Smart & Efficient! Runtian Power in The Construction of Zhuhai-Zhaozhou High-Speed Railway

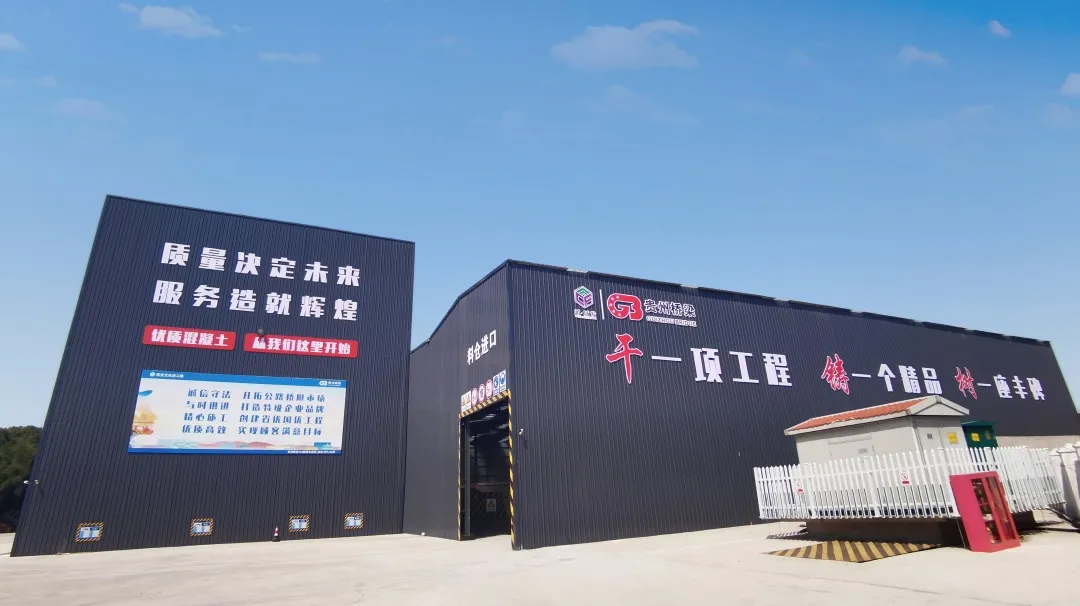

Recently, in Zhaoqing, Guangdong, two sets of HZS180 concrete Batching Plants of Runtian Zhike were applied to the Zhuhai-Zhaozhou high-speed railway project, providing strong equipment support for the construction of the project and contributing to the production of high-quality concrete.

The Zhuhai-Zhaozhou high-speed railway, located in Guangdong Province, is a major project to improve the layout of the railway network on the west bank of the Pearl River Estuary, among which the section from Jiangmen to the hub airport of the Pearl River Delta is an important part of the Shenzhen-Nanning high-speed railway, which will realize the rapid connection between the east and west banks of the Pearl River and the southwest region, and is of great significance for making up for the shortcomings of the railway on the west bank of the Pearl River and promoting the coordinated development of the east and west banks of the Pearl River.

At present, the two HZS180 production lines of the project are running stably, and have continued to produce Cement Concrete for the key project, with stable quality and excellent quality.

The customer said that in the production process, the mixing efficiency of the two sets of equipment is very high, and the project has very strict requirements for the quality and stability of the product, and the concrete produced by Runtian Zhike equipment fully meets these requirements.

Runtian Zhike's batching plant products adopt modular design, compact structure, easy installation, and can be put into use quickly. According to the customer's production target, the two production lines are equipped with a total of 16 cement tanks of 200 tons, which can meet the needs of large-scale and complex ratio concrete production.

Secondly, the mixing plant has a high degree of intelligence and is equipped with an intelligent production control system, which can realize dual-control and dual-machine control and remote centralized control, which greatly improves the production and management level.

Intelligent production control system

Dual-control dual-machine control system

One person controls two production lines to save human resources; Multiple production lines are concentrated in one control room, and laboratories, scheduling, and operators are centralized to improve management efficiency;

Remote centralized control system

Laboratory personnel and dispatchers can monitor and intervene in production in time to prevent production errors and improve concrete quality;

Improve the office environment by moving operators from noisy, dusty environments to quiet, clean control rooms.

The equipment performs well in the production of the project, which provides a reliable guarantee for the smooth construction of customers; The stable operation of the equipment ensures the quality and progress of the project.

In the future, Runtian Zhike will continue to uphold the service concept of customer first, continuously innovate and improve the product and service system, and work together with customers to make greater contributions to the construction of the project.

HZS Series Belt Concrete Mixing Plant

HZS Series Belt Concrete Mixing Plant HZS Series Bucket-Lifting Type Container Concrete Mixing Plant

HZS Series Bucket-Lifting Type Container Concrete Mixing Plant HZS60 Mobile Concrete Mixing Plant

HZS60 Mobile Concrete Mixing Plant HZS Series Bucket-Lifting Type Concrete Mixing Plant

HZS Series Bucket-Lifting Type Concrete Mixing Plant HZS Series Mobile Concrete Mixing Plant

HZS Series Mobile Concrete Mixing Plant HZS Series Top-Mounted Concrete Mixing plant

HZS Series Top-Mounted Concrete Mixing plant HZS Series Semi-Top Mounted Concrete Mixing Plant

HZS Series Semi-Top Mounted Concrete Mixing Plant WDB Series Foundation-Free Stability Soil Mixing Plant

WDB Series Foundation-Free Stability Soil Mixing Plant LCB Series Emulsified Asphalt Cold Regeneration Secondary Mixing Plant

LCB Series Emulsified Asphalt Cold Regeneration Secondary Mixing Plant LB Series Asphalt Mixing Plant

LB Series Asphalt Mixing Plant LBR Series Integrated Asphalt Mixing Plant

LBR Series Integrated Asphalt Mixing Plant LBRN Series Counterflow Integral Asphalt Mixing Plant

LBRN Series Counterflow Integral Asphalt Mixing Plant RZS Series Asphalt Mixing Plant

RZS Series Asphalt Mixing Plant RTZS120 Series RAP Crushing & Screening Plant

RTZS120 Series RAP Crushing & Screening Plant RTPF350DS Crawler Mobile Impact Crushing Plant

RTPF350DS Crawler Mobile Impact Crushing Plant RT116JH Crawler Mobile Jaw Crushing Plant

RT116JH Crawler Mobile Jaw Crushing Plant RT116JE Crawler Mobile Jaw Crushing Plant

RT116JE Crawler Mobile Jaw Crushing Plant RT300CE Crawler Mobile Cone Crushing Plant

RT300CE Crawler Mobile Cone Crushing Plant RT300CH Crawler Mobile Cone Crushing Plant

RT300CH Crawler Mobile Cone Crushing Plant RT5015H Mobile Scalping Screen

RT5015H Mobile Scalping Screen RT315VSIE Crawler Mobile Sand Maker

RT315VSIE Crawler Mobile Sand Maker RT3YK6020 Crawler Mobile Screening Plant

RT3YK6020 Crawler Mobile Screening Plant RT3YK6020M Modular Screening Plant

RT3YK6020M Modular Screening Plant RTF260M Modular Counterattack Crushing and Screening Integrated Machine

RTF260M Modular Counterattack Crushing and Screening Integrated Machine RTF350M Modular Impact Crushing Plant

RTF350M Modular Impact Crushing Plant RTF450M Modular Impact Crushing Plant

RTF450M Modular Impact Crushing Plant Construction Waste Resourceful Treatment Line

Construction Waste Resourceful Treatment Line