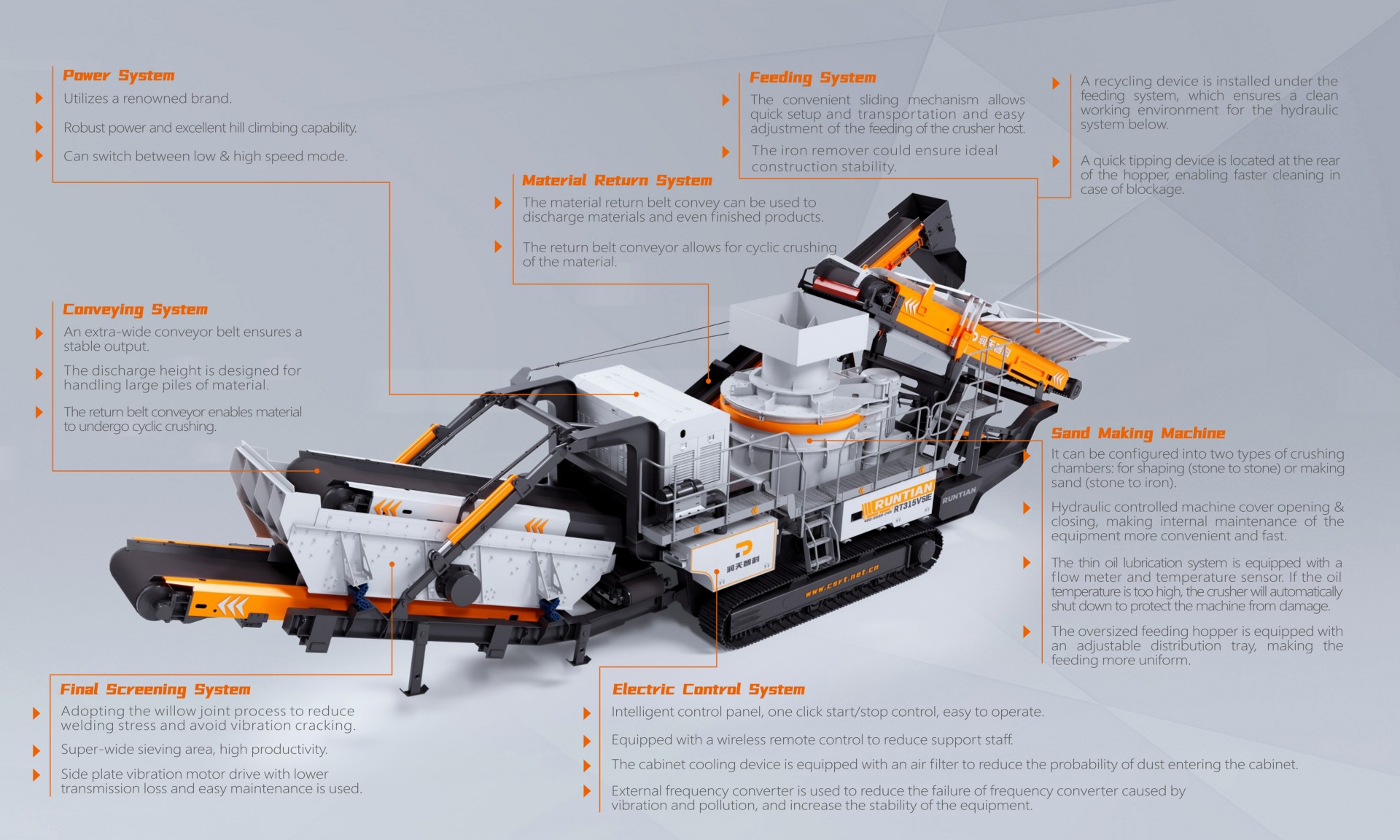

RT315VSIE Crawler Mobile Sand Maker

Product Parameters

| Feeding Device | Max.feeding Size 40mm |

| Feeding Height 3000mm | |

| Hopper Volume 3m³ | |

| Feeding Capacity 300t/h | |

| Crusher | Crusher Model SK2400 |

| Crusher Motor Power 315kW | |

| Main Conveying Belt | Belt Width B1000mm |

| Power 15kW | |

| Mixed Material Conveying Belt | Belt Width B1000mm |

| Power 7.5kW | |

| Returned Material Conveying Belt | Belt Width B650mm |

| Power 5.5kW | |

| Transmission Conveying Belt | Belt Width B500mm |

| Power 3kW | |

| Whole Machine | Total Power 364.5kW |

| Total Weight 55t | |

| Working Mode External Power Supply | |

| Working Dimension 18.5mx3.9mx5.1m | |

| Transportation Dimension 20mx3.9mx3.8m |

Product characteristics

01

Continuous Feeding

The crusher is equipped with an oversized feeding hopper which is equipped with an adjustable dividing plate inside to ensure uniform feeding and make the material particle shape more rounded and stable.

02

Linkage Control

The thin oi lubrication system of the crusher host is equipped with a flow meter and temperature sensor f the oil temperature is too high, the crusher and various conveyors will automatically shut down to protect the machine from damage.

03

Pre-sieving

The crusher is equipped with pre-sieving system, which can increase the output of the entire equipment.

04

Transportation & Maintenance

The entire machine is equipped with a hydraulic control system. which can switch the working and transportation status of the equipment by controlling the hydraulic cylinder. internal maintenance and replacement of vulnerable parts of the equipment can also be opened by controlling the hydraulic cylinder.

05

Dust removal & Environment protection

The equipment is equipped with sprinkler system, and external spraying can effectively reduce dust in the air. The circulating flow of air inside the crushing chamber can effectively guide the flow of internal dust, and there is a sealing device at the discharge position, which can greatly reduce the inflow of internal dust into the outside.

07

One Machine for Multiple Purpose

The crusher can change the purpose of the equipment by adjusting the cavity shape, and there are multiple cavity shapes to choose from, including “iron to iron” “stone to iron”, and “stone to stone”. It can be used for shaping sand and gravel aggregates and sand making operations, which has high flexibility.

08

Closed Loop Material Cycling

The crusher is equipped with a material circulation system, sand & gravel aggregates that do not meet the requirements can be re-fed into the crusher for crushing. Of course, this part of sand and gravel aggregates can also be used as end materials.

Function module

01

Power System

02

Conveying System

03

Material Return System

04

Feeding System

05

Final Screening System

06

Electric Control System

07

Sand Making Machine

description2

HZS Series Belt Concrete Mixing Plant

HZS Series Belt Concrete Mixing Plant HZS Series Bucket-Lifting Type Container Concrete Mixing Plant

HZS Series Bucket-Lifting Type Container Concrete Mixing Plant HZS60 Mobile Concrete Mixing Plant

HZS60 Mobile Concrete Mixing Plant HZS Series Bucket-Lifting Type Concrete Mixing Plant

HZS Series Bucket-Lifting Type Concrete Mixing Plant HZS Series Mobile Concrete Mixing Plant

HZS Series Mobile Concrete Mixing Plant HZS Series Top-Mounted Concrete Mixing plant

HZS Series Top-Mounted Concrete Mixing plant HZS Series Semi-Top Mounted Concrete Mixing Plant

HZS Series Semi-Top Mounted Concrete Mixing Plant WDB Series Foundation-Free Stability Soil Mixing Plant

WDB Series Foundation-Free Stability Soil Mixing Plant LCB Series Emulsified Asphalt Cold Regeneration Secondary Mixing Plant

LCB Series Emulsified Asphalt Cold Regeneration Secondary Mixing Plant LB Series Asphalt Mixing Plant

LB Series Asphalt Mixing Plant LBR Series Integrated Asphalt Mixing Plant

LBR Series Integrated Asphalt Mixing Plant LBRN Series Counterflow Integral Asphalt Mixing Plant

LBRN Series Counterflow Integral Asphalt Mixing Plant RZS Series Asphalt Mixing Plant

RZS Series Asphalt Mixing Plant RTZS120 Series RAP Crushing & Screening Plant

RTZS120 Series RAP Crushing & Screening Plant RTPF350DS Crawler Mobile Impact Crushing Plant

RTPF350DS Crawler Mobile Impact Crushing Plant RT116JH Crawler Mobile Jaw Crushing Plant

RT116JH Crawler Mobile Jaw Crushing Plant RT116JE Crawler Mobile Jaw Crushing Plant

RT116JE Crawler Mobile Jaw Crushing Plant RT300CE Crawler Mobile Cone Crushing Plant

RT300CE Crawler Mobile Cone Crushing Plant RT300CH Crawler Mobile Cone Crushing Plant

RT300CH Crawler Mobile Cone Crushing Plant RT5015H Mobile Scalping Screen

RT5015H Mobile Scalping Screen RT315VSIE Crawler Mobile Sand Maker

RT315VSIE Crawler Mobile Sand Maker RT3YK6020 Crawler Mobile Screening Plant

RT3YK6020 Crawler Mobile Screening Plant RT3YK6020M Modular Screening Plant

RT3YK6020M Modular Screening Plant RTF260M Modular Counterattack Crushing and Screening Integrated Machine

RTF260M Modular Counterattack Crushing and Screening Integrated Machine RTF350M Modular Impact Crushing Plant

RTF350M Modular Impact Crushing Plant RTF450M Modular Impact Crushing Plant

RTF450M Modular Impact Crushing Plant Construction Waste Resourceful Treatment Line

Construction Waste Resourceful Treatment Line